- Browse Products

- Cheese equipment

- Filling – conveyers – handling

- Heat exchangers & HTST

- Homogenizers

- Instrumentation & Control

- Miscellaneous

- Pump – Centrifugal

- Pump – Other

- Pump – Positive displacement

- Separators – decanteurs – clarifiers

- Storage tanks & processors

- Valve – Angle seat

- Valve – Ball valve

- Valve – Butterfly

- Valve – Control

- Valve – Mixproof

- Valve – Other

- Valve – Seat

- Washing equipment

- About Us

- Contact Us

- Your selection

- Français

Conditionning line for yogurt cup 113004422

$125,000.00

Conditionning line for yogurt cup

Ampack Ammann L/AA5

– Nominal cadence : 12000 units/hr, 40cycles/min

– Operational cadence : 11400 units/hr, 38 cycles/min

– 5 rows of 142g-156g individual cup, 73mm, 5oz, 6oz. Can do up to 200g cup.

– Overall dimensions : 24 ft lenght, 5 ft depth, 7ft hight

– Power panel dimensions : 6ft length, 2ft depth, 7ft hight

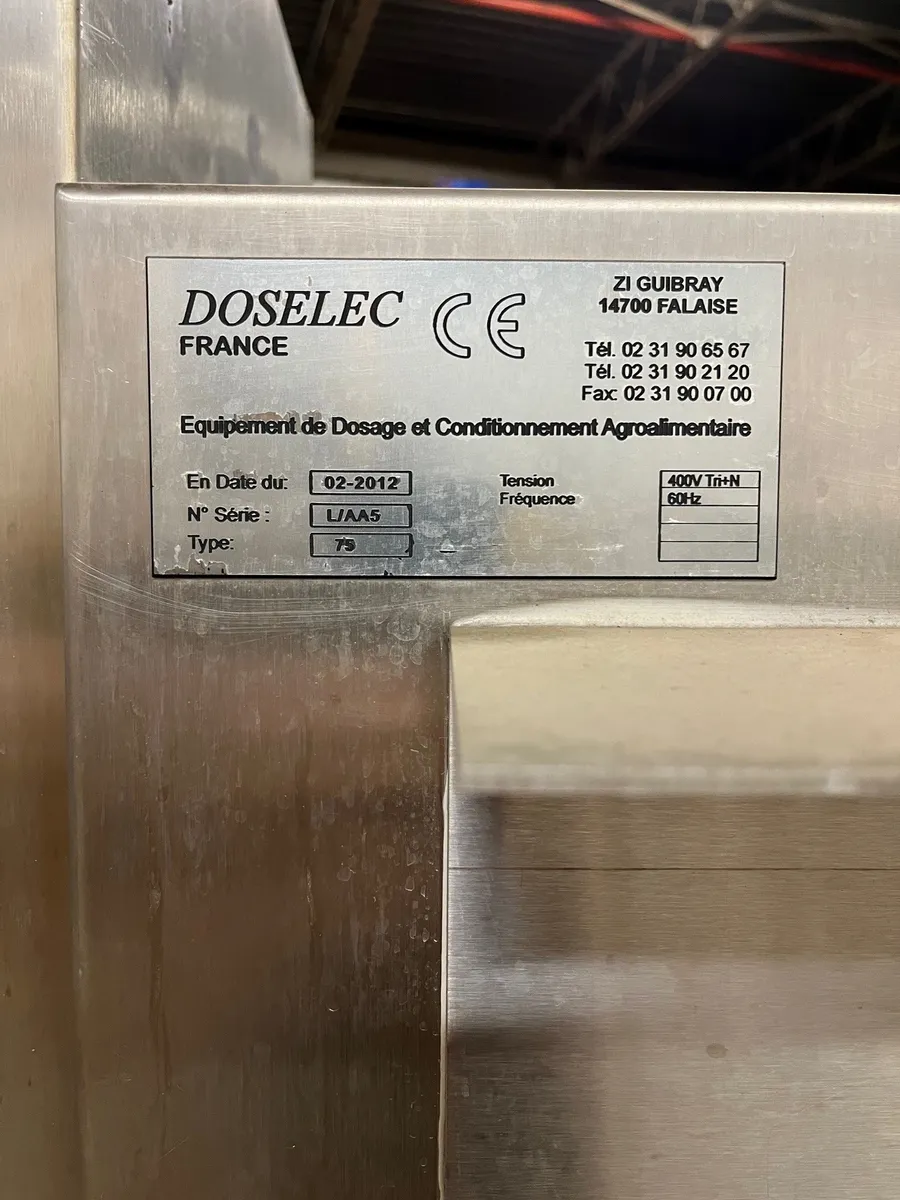

– Power panel rebuild by Doselec. This panel manage all the automation of the filler line.

– All the mechanical system under the filler has been refurbished

– CIP system integrated. Manage to clean all the surfaces in contact with the food.

– Automated cup feeder to the filler line.

– Fruit dosage system refurbished by Doselec.

– Yogurt dosage system refurbished by Doselec.

– Aluminium operculum distribution system.

– Thermal sealing system for operculum

– Inkjet coding system in place without the coding printer (Markem-Imaje system)

– Sealing quality validation station

– Boxes charging station