Your search ends here!

- Browse Products

- Cheese equipment

- Filling – conveyers – handling

- Heat exchangers & HTST

- Homogenizers

- Instrumentation & Control

- Miscellaneous

- Pump – Centrifugal

- Pump – Other

- Pump – Positive displacement

- Separators – decanteurs – clarifiers

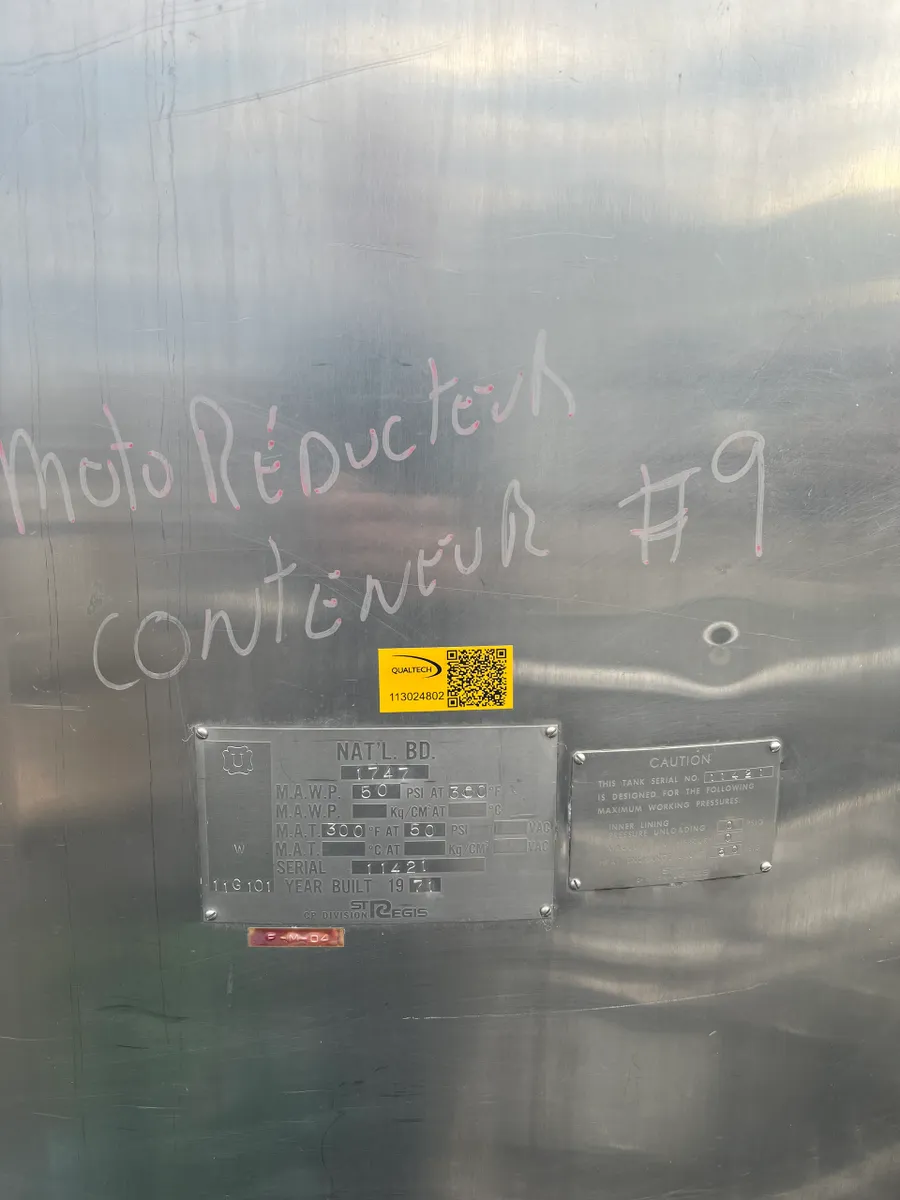

- Storage tanks & processors

- Valve – Angle seat

- Valve – Ball valve

- Valve – Butterfly

- Valve – Control

- Valve – Mixproof

- Valve – Other

- Valve – Seat

- Washing equipment

- About Us

- Contact Us

- Your selection

- Français

About who we are

You may know Qualtech for its high-quality cheese & dairy equipment or turnkey projects, but did you know that we also offer second life on preowned Cheese & dairy processing equipment? We offer a wide range of used equipment, from storage tanks to cheese vats, to finishing tables, homogenizers, plate heat exchangers, separators and much more!

Whether you are expanding production at your plant, looking for replacement equipment, or starting a new operation, we have what you need with a lower investment cost and quicker delivery. This equipment can be sold in an ‘’as-is’’ state or completely refurbished condition. View our inventory below or contact us directly with your request.

Our newest additions

Our products are worry free and in working conditions

Service

We provide a calibration service for milk pasteurization systems. Our team can help you calibrate and check your instruments. We also offer a maintenance service for valves, pumps, heat exchangers and separators/homogenizers.

Need new custom equipment?

We got you covered!

Testimonials

-

I have worked with Qualtech steadily both in Manitoba and other provinces over the last 4 years. They have done everything from piping entire process rooms, installing tanks, mezzanines to small, odd jobs like hooks. I have them quote on all major projects I personally do as they are always competitive. They are reliable and great at addressing issues before they are a problem. The quality of work is consistent and dependable. Qualtech also has a solution to any parts or general inquires that I need making them a good source of knowledge to have on a project site.

Curtis Bowman, Saputo -

I’ve been working with Qualtech for several years, mainly with its president, who puts all his energy into serving his customers well. I’m always amazed at the excellent work he delivers every time, and the quality of the work done by their engineers and welders, which means I’m more than satisfied with the job done. (Straight piping and speed of execution). With the fines filter, we were able to introduce our fines directly into the cheese being made. The HTST allows us to lower the water temperature to cool our whey more efficiently without any additional energy thanks to the energy recovery system. Repairs to the curdling unit went very smoothly, with no worries, as we have complete confidence in the work team. The automation of the fermenter has enabled us to save time and human intervention for a more uniform and consistent product.

Michel Choquette, Président Fromagerie La Chaudière -

Qualtech has carried out several automation projects at Agropur’s Cheese plant in Corneville. Their expertise and professionalism have always lived up to our expectations, whether we’re setting up a new plant or starting up a new project.

Mario Labonté Agent de Développement Corporatif, Agropur -

I’ve been dealing with Qualtech for over 10 years, having gone through several phases of rapid industrial growth during this period. The advantages of Qualtech for me are: technical competence, transparency and flexibility. Qualtech has become a logical choice in the design, manufacture, and process provider.

Normand Champagne, Liberté St-Hyacinthe

Authorized distributor